Maintenance

Reliability and Redundancy

Mission critical equipments main function should be to provide constant uptime. However, when unplanned outages happen, operations must be proactive in finding ways to prevent them. Lack of experience, procrastination, and perceived savings to OPEX are not acceptable excuses after your worst nightmare becomes a reality.

Understanding the cause of outages and finding ways to address the mare crucial to preventing business disruption that can lead to customer loss and damaged reputations.

Recent studies show UPS battery failure is responsible for more than 25% of outages. Just as critical is your generator and the switchgear which operate your LSI and PLC controllers. Are you being proactive in maximizing their life? The second leading cause of outages is human error. Do you have all operations documented and are all personnel trained?

The MDI Perspective – What We Deliver

Step-by-Step – MDI will help you in developing a comprehensive preventative maintenance program or the re-commissioning of your critical equipment. MDI is your single source solution in the ongoing maintenance of any or all of the following:

UPS Systems

Battery Systems for UPS/Switchgear, Telecom

Battery Monitoring Systems

PDU

DC Power Plants

Inverters

Static

Switches

Generators

Busway Systems

Surge Suppression

IR Ports

Infrared Thermography of Electrical Panels

Our Approach

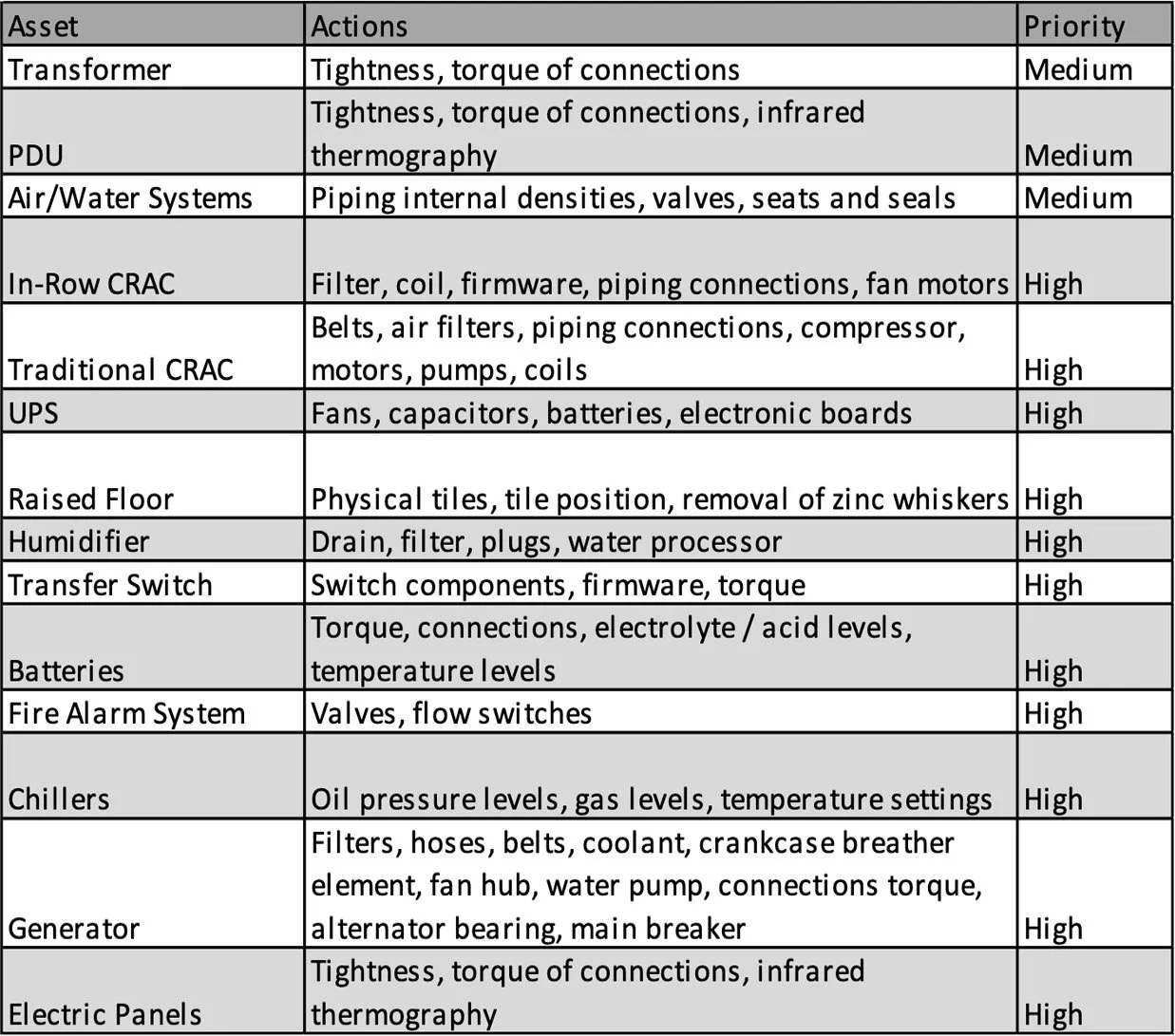

A comprehensive maintenance program is about more than just batteries. Let MDI create a Preventative Maintenance (PM) program that is tailored to your needs and exact situation. The following is a sample list of infrastructure assets that require a PM program. Its important to note, that none of these systems are stand-alone - they need to be maintained as an integrated system by a provider that understands the inter-relationship and inter-dependencies of the system as-a-whole. Our deliverables will include an accurate asset inventory, recommended actions, and priority level. In addition, we include a 5-year maintenance calendar with annual check ups to the list and calendar. MDI will help establish end of life policies.

Work with Industry Professionals with real world experience in design, installation and maintenance

A Vendor Neutral Supplier who offers stakeholders a comparative

assessment of a broad array of proposed provider solutions &

capabilities

Providing a Comprehensive Understanding of your mission critical

equipment requires an understanding of how other assets in the

facility will be integrated into the total solution

A Variety of Solutions Offerings: MDI is a single source for a wide variety of equipment maintenance